Application and future development of diaphragm compressors in hydrogenation filling stations

Application and future development of diaphragm compressors in hydrogenation filling stations

As the core equipment of the hydrogenation station, the safety of the diaphragm compressor is first and foremost. Safety must be considered in product design, material selection, manufacturing, inspection and testing. For domestic hydrogen refueling stations already operating, everyone is very concerned about the exhaust temperature of the compressor, the diaphragm service life, and the reliability of the equipment operation, especially the issue of the exhaust temperature. Our company has also specifically analyzed this issue. , SH / T3143-2012 "Engineering Technical Regulations for Reciprocating Compressors in Petrochemical Industry" Article 5.3.2 stipulates that: for a hydrogen-rich gas medium with a molecular weight of less than or equal to 12, when the cylinder has no oil lubrication, when the gas pressure is greater than or equal to 7MPaG Under all specified operating conditions and load conditions, the expected exhaust temperature should be less than or equal to 130 ° C. The alarm value is 10 ° C higher than expected, and the shutdown value should be 20 ° C higher than expected. The exhaust port of each cylinder should have a separate detection point, and it should be as close as possible to the cylinder exhaust valve. This regulation is actually considered from the perspective that hydrogen gas can easily cause hydrogen embrittlement on steel pipes. High exhaust temperature not only affects the compressor's working efficiency and transmission lubrication, but most importantly involves safety issues.

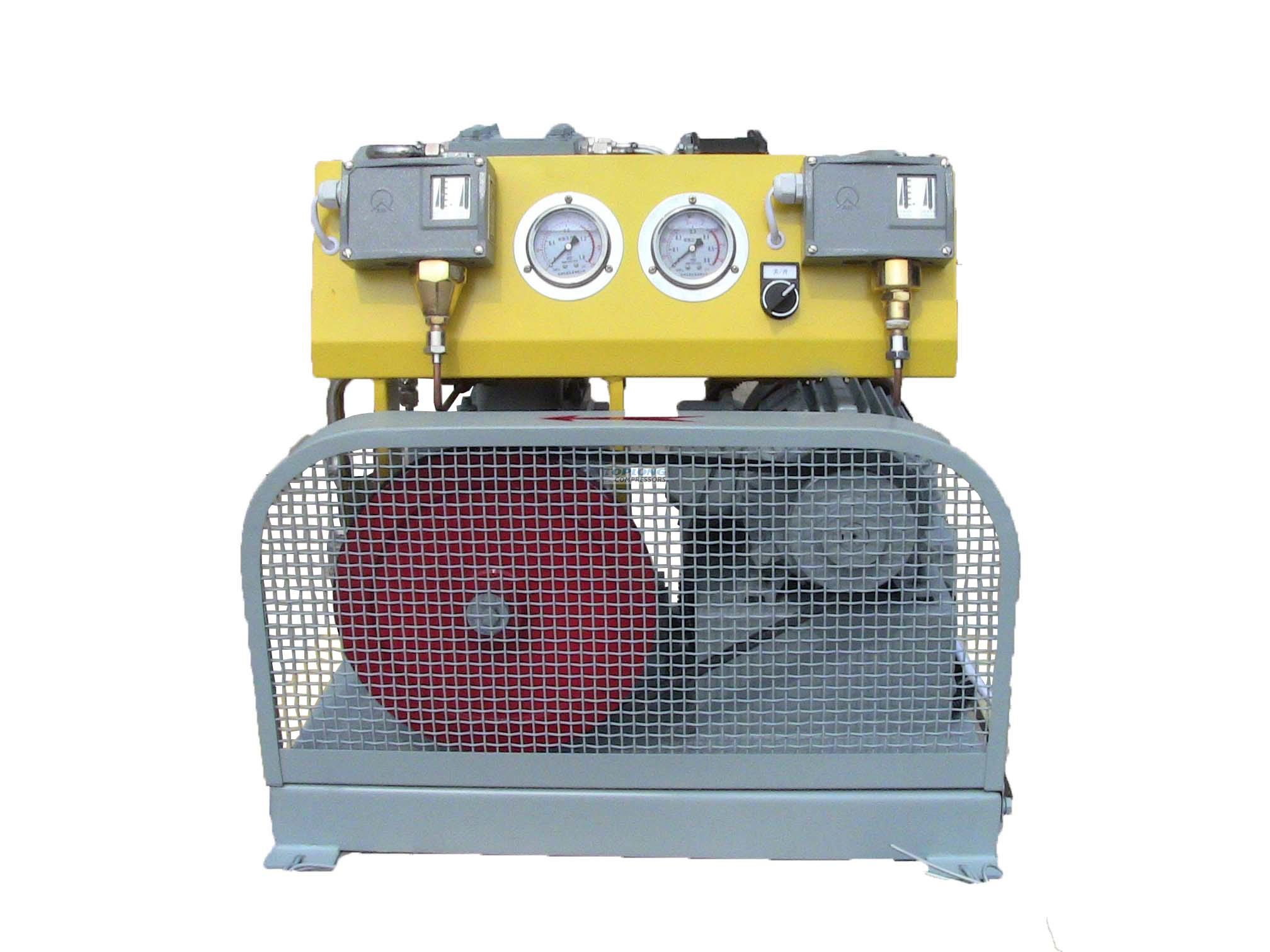

The application scenarios of diaphragm compressors for hydrogen refueling stations are different from traditional diaphragm compressors. Except that the compressor discharge pressure is extremely high, operators inside the station do not know the equipment and are not familiar with the operation. It is also a common situation. Therefore, the development trend of diaphragm compressors for hydrogen refueling stations is unattended, which is what we usually call automatic light-load start-stop. Operators only need to recognize the start and stop buttons. In addition, diaphragm compressors for hydrogen refueling stations require suppliers to have a big improvement in product after-sales service. In addition to equipment operation troubleshooting, even replacement of spare parts requires service.

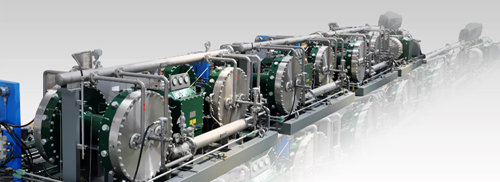

At present, there are some piston compressors used in hydrogenation stations abroad. What is the difference between this type of product and the diaphragm compressor?

Both hydrogen piston compressors and hydrogen diaphragm compressors have their advantages. The output of piston products is large, which has advantages over diaphragm compressors, but because piston compressors compress hydrogen in the reciprocating motion of the piston, it will pollute the hydrogen, and it is easy for hydrogen to leak, and at the same time, the exhaust temperature is too high. It is easy to solve, these factors make this product have some problems to be solved in the application of hydrogen energy. The characteristics of the diaphragm compressor are that it does not cause any pollution or leakage to the compression medium, and the compression cavity has good heat dissipation. It can adopt a high compression ratio and easily achieve ultra-high pressure.

In addition to the hydrogenation station is a great development opportunity for the diaphragm compressor, the associated gas recovery in the petroleum industry and the electronic gas in the chip field, the diaphragm compressor also has broad application space.