What are the applications of diaphragm compressors?

What are the applications of diaphragm compressors?

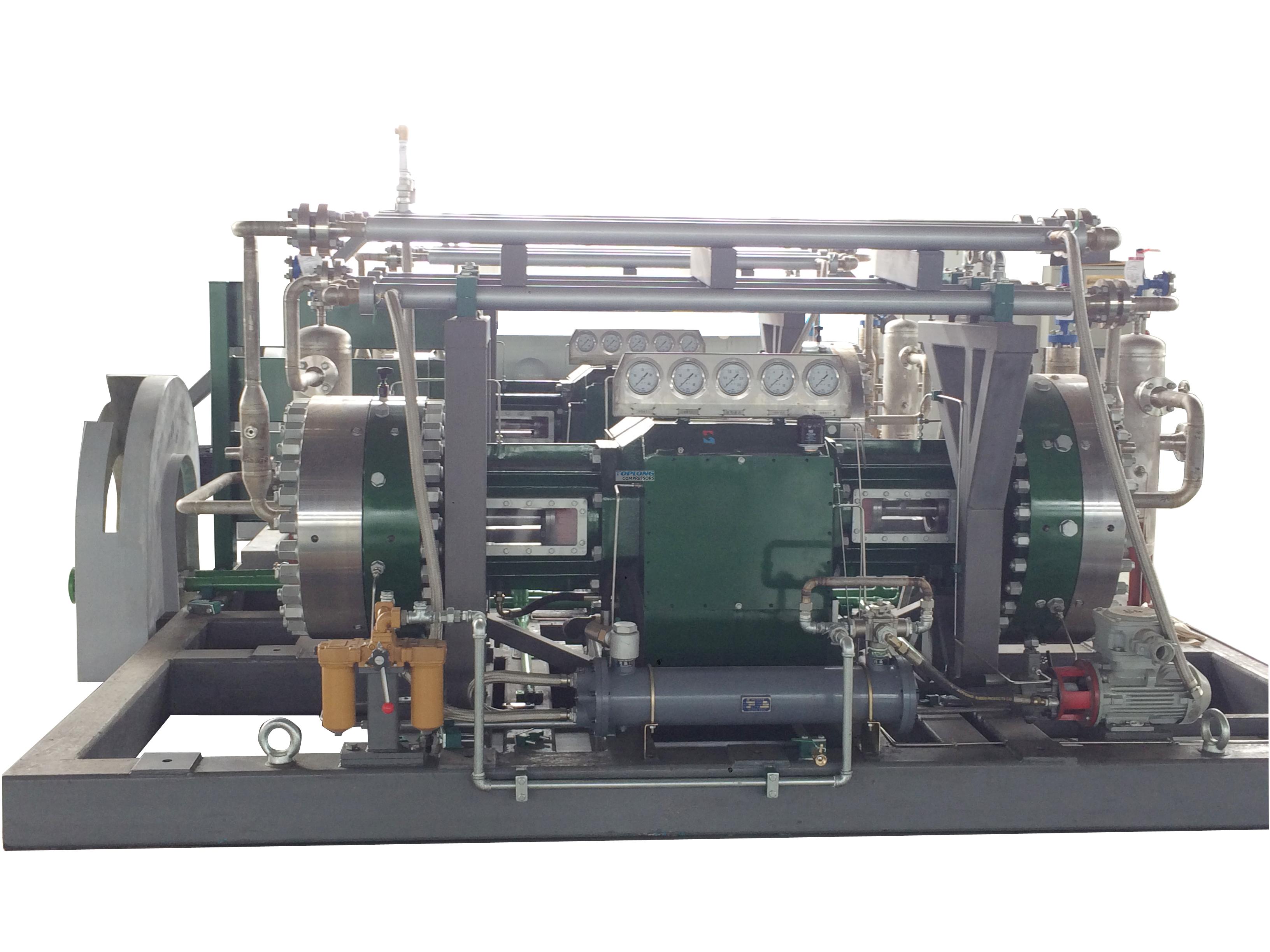

Diaphragm compressor is a special type of positive displacement compressor, with good sealing, high compression ratio, high gas purity and other advantages, widely used in the following fields:

一、Gas filling

Hydrogen Refilling: In fuel cell vehicle refueling stations, diaphragm compressors are used to compress hydrogen gas to specified pressure for storage in the vehicle's high-pressure hydrogen storage tank. Given hydrogen's flammable and explosive nature, these compressors feature robust sealing systems that effectively prevent leaks, ensuring a safe refueling process.

Special gas filling: For some high purity, rare or expensive special gases, such as helium, neon, krypton and so on, diaphragm compressor can compress and fill them into steel cylinders or other storage containers, meet the demand of electronic, scientific research, medical and other fields for special gases, while ensuring that the purity and quality of gas is not polluted.

二、Chemical Industry

High-pressure synthesis reactions: In chemical production, numerous synthesis processes require high-pressure conditions. For example, in ammonia synthesis, nitrogen and hydrogen are compressed to high pressure before reacting with a catalyst to produce ammonia. Diaphragm compressors provide a stable high-pressure gas supply that meets reaction requirements while preventing chemical reactions or contamination by avoiding contact between the compressed medium and external environments.

Gas Transportation and Storage: In chemical production processes, various gases need to be transported and stored across different equipment systems. Diaphragm compressors are used to compress gases such as chlorine, acetylene, and ethylene to appropriate pressures. These compressed gases can then be transported through pipelines to designated locations or stored in high-pressure storage tanks, providing raw materials for subsequent production stages.

三、Electronic industry

Semiconductor Manufacturing: In semiconductor chip production, various high-purity gases such as silane, ammonia, and oxygen are essential. Diaphragm compressors are employed to compress these gases to specific pressures and deliver them to chip manufacturing equipment, ensuring precise gas supply for processes including thin film deposition, etching, and doping. Their high-precision compression control and excellent sealing performance help maintain the quality and consistency of chip manufacturing.

LCD and OLED Manufacturing: During the production of LCD and OLED panels, specialized gases such as fluorine and xenon are required. Diaphragm compressors can compress these gases to appropriate pressures for processes like coating and photolithography, ensuring stable manufacturing processes and high-quality products.