Do you know the working cycle process of the diaphragm compressor?

Do you know the working cycle process of the diaphragm compressor?

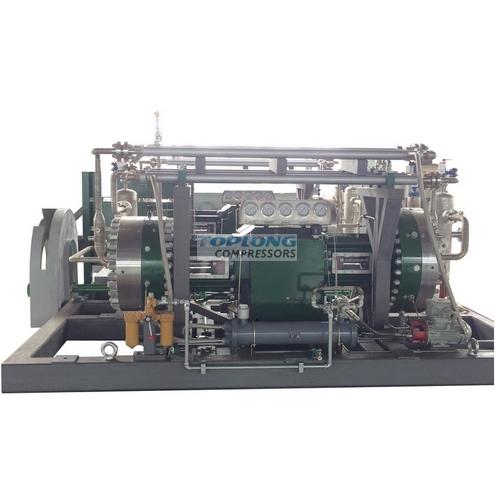

When the piston rod of the diaphragm compressor is at the outer stop point, the diaphragm compressor diaphragm causes deformation after pressing close to the slope of the cylinder head, and the steam body in the air cavity has been discharged, but the residual gas still has high pressure because of the residual gap capacity. When the hydraulic cylinder piston rod inward check point bearing fitness movement, oil cavity fluid working pressure slowly reduced until fade, pressure difference occurs on both sides of the diaphragm, the diaphragm in the steam residual pressure and itself deformation force effect gradually shrink deformation, cavity capacity expansion, standard pressure gradually reduced, when the cavity standard pressure is lower than the suction air pressure, suction valve automatic open, the whole process of breathing gradually.

The diaphragm compressor manufacturer introduced that when the piston rod again to the inner stop point orientation fitness exercise, the diaphragm in the pressure difference effect again to the oil cavity side deformation, when the hydraulic cylinder reciprocated movement to the inner stop point part, the diaphragm shape changes to the lower limit part.

The suction valve is turned off, and the whole breathing process is finished. Piston rod gradually outward check point fitness exercise, oil working pressure is gradually rising, diaphragm to the outer check point bearing deformation, cavity capacity slowly narrowed, when the air pressure in the cavity exceeds the standard pressure in the exhaust pipe, automatic exhaust valve open, reduce the whole process until the hydraulic cylinder reciprocating movement to the outside stop point, when the diaphragm close to the cylinder head, automatic exhaust valve shut off, the whole process of exhaust pipe, to do a working circulation system.

In each work of the refrigeration compressor circulation system, diaphragm compressor price oil in the hydraulic cylinder by hydraulic cylinder piston rod leakage or caused by the pressure relief valve discharge slightly more residual oil damage, and is likely to maintain the required oil working pressure, so in each work circulation system must fill in the oil cavity.

The stop ring on the front of the engine crankshaft promotes the filling gasoline pump to fill the oil into the oil cavity in each working circulation system. The residual oil filled in the whole process of each cycle system, the unnecessary part of the residual oil is discharged by the yellow pressure regulator at the upper end of the oil cavity. In addition, the yellow force size of the pressure reducing valve is used to discharge the residual oil, and then carry out smooth adjustment of the steam pressure.