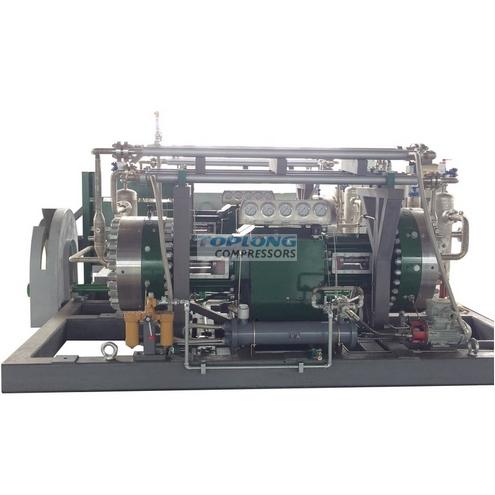

Application of a methane compressor

Application of a methane compressor

Methane compressor plays an important role in many fields, mainly including the following aspects:

1.Natural gas storage and transportation: The methane compressor can compress low pressure natural gas into a high pressure state, making it easily stored in high pressure vessels, which not only improves the safety of the storage system, but also provides the possibility of remote transmission of natural gas.

2.Industrial and civil applications: compressed natural gas can be used as a power source, widely used in logistics and transportation, underground mining, civil natural gas and natural gas power generation and other fields. Its efficient and environmentally friendly characteristics make it an important part of the modern energy system.

3.CBM mining and transportation: During the mining and transportation of the coalbed methane, the methane compressor increases the pressure by reducing the volume of the gas, so that it can be extracted from underground and compressed to an appropriate pressure level for subsequent treatment and utilization.

operational principle

The working principle of a methane compressor is based on the fundamental principles of gas compression. By performing work on the gas through the impeller, it utilizes the centrifugal pressure increase and deceleration expansion effects to convert mechanical energy into the pressure energy of the gas. Specifically, the gas's pressure increases as it rotates in the impeller, and then further pressurizes in the diffuser.

Types and Features

There are many types of methane compressors, each with its own unique characteristics and applicable scenarios:

Piston compressor: simple structure, suitable for small-scale or low-pressure applications.

Screw compressor: smooth operation, low noise, high energy efficiency, widely used in a variety of industrial fields.

Centrifugal compressor: suitable for large-scale, high-pressure application scenarios, with the advantages of large processing capacity and high efficiency.

These compressors usually have the characteristics of high efficiency, energy saving, stable operation, safety and reliability, which can meet the needs of various application scenarios.