How to solve the system air leakage problem of the diaphragm compressor?

How to solve the system air leakage problem of the diaphragm compressor?

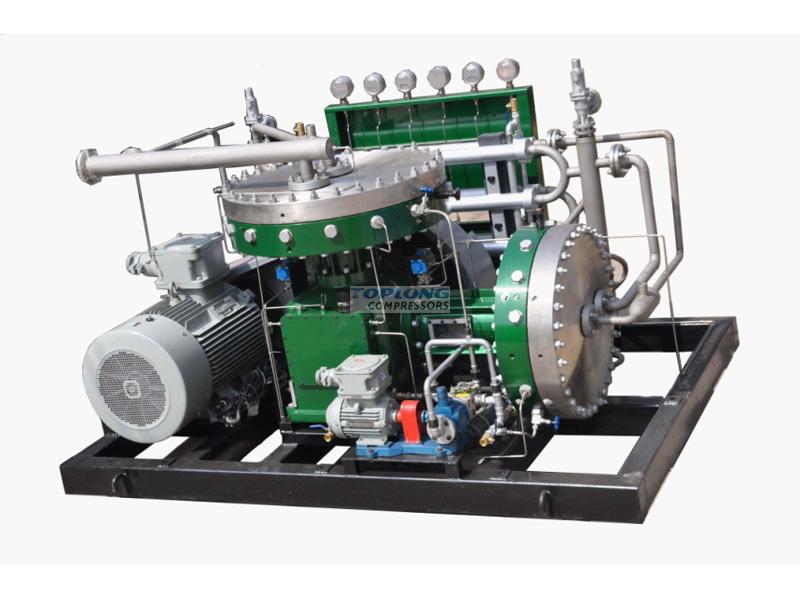

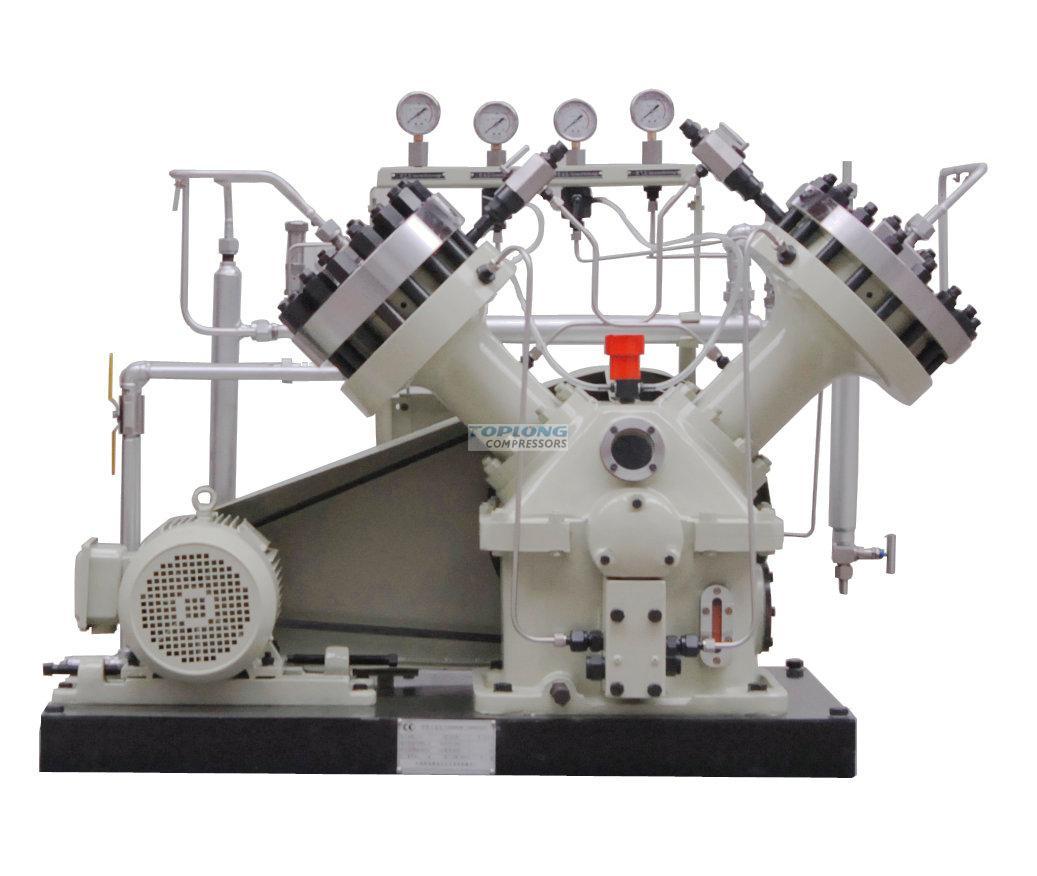

Diaphragm compressor is a commonly used air compressor, which in the working process, through the diaphragm will be separated from the gas, so as to compress the gas. However, the diaphragm compressor may leak air during operation. System leakage will lead to energy waste and equipment failure, so it is very important to solve the system leakage problem to ensure the normal operation of the diaphragm compressor.

First, we need to find the source of the air leak. For diaphragm compressors, the main leakage source is the diaphragm and seals. Therefore, we first need to check whether the diaphragm and seals are wear, aging, damage and other conditions. If a problem is found, it needs to be replaced in time.

Secondly, for pipe joints and valves and other components, we need to carefully check and adjust. Air leakage is often caused by uncomponent parts, so we need to check whether each connection is fastened. If loose is found, it should be tightened with wrench and other tools in time.

In the process of solving the problem of air leakage, we also need to pay attention to the following points:

Add sealing materials: For some unnecessary sealing positions, we can add sealing materials, such as PFE film, at the joints.

Use sealant: for some old seals or parts prone to air leakage, we can use sealant for repair. The sealant can fill in the leakage gaps, thus preventing gas leakage.

Regular maintenance: the diaphragm compressor needs regular maintenance, including replacement of lubricant, cleaning of filter element, adjusting valve, etc. Regular maintenance can find and solve the air leakage problem in time, so as to ensure the normal work of the diaphragm compressor.

Update equipment: If the leakage problem is serious and cannot be solved, we may need to consider replacing the diaphragm compressor. New equipment usually has better sealing performance and durability, which can effectively solve the problem of system air leakage.

In short, to solve the problem of diaphragm compressor system needs a comprehensive and systematic inspection and treatment. Only by finding the air leakage source and taking the correct remedial measures, can we ensure the normal operation of the diaphragm compressor. At the same time, regular maintenance and update of equipment is also an important means to prevent air leakage problems. Through these measures, the energy waste can be more reduced and the service life of the equipment can be extended.