Description

Our high pressure nitrogen compressors are manufactured to stringent standards to meet some of the world’s toughest demands. With design pressures of up to 7,280 psi, GreenField has met the challenges of compressing light gases, highly explosive gases, and toxic gases. Additionally, HIT compressors have been utilized in applications that require high purity standards to be maintained.

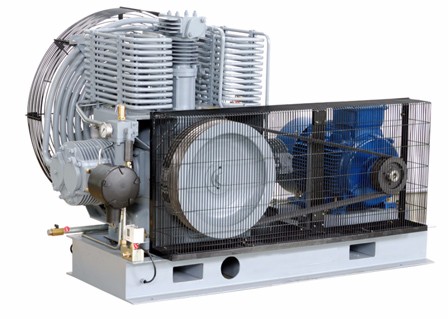

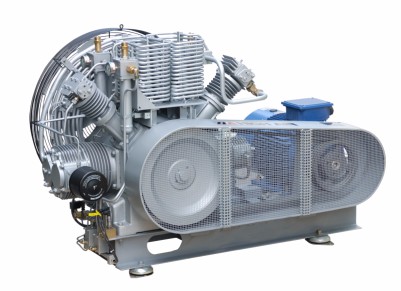

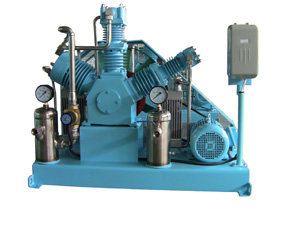

The compressors feature a rugged skid designed for the rigors of transporting a compressor from site to site. The skid is fabricated of heavy steel plate reinforced by structural members. The standard skid comes equipped with forklift slots for ease of movement.

The compressor is a trunk piston style compressor. It is derived from a proven oil field compressor frame that has been modified for the demands of high-pressure compression. The frame is then equipped with air-cooled cylinders, permitting higher compression ratios and better efficiency. The compressor is balanced so that, in most cases, the compressor can be run on a high-density rubber pad, and does not require a special foundation.

Critical shutdowns include a high discharge gas temperature switch, low oil pressure switch, and a high discharge gas pressure switch (final stage).

Additional equipment include an air cooled heat exchanger after each stage of compression (water cooled heat exchangers available as an option), pressure safety valves after each stage of compression, all internal skid piping, personnel guards over rotating components, a separator after each stage of compression, and an automatic condensate drain system.

Compressor Specification

Designed for maximum efficiency.

Our compressors feature interchangeable cylinders, cylinder heads, pistons and valves.

We can offer compressors customized for wide ranges of pressure and volume at highly competitive prices.

Operates at low RPM, low compression ratios and low temperatures for greater efficiency and longer operating life.

No special foundation required; compressors can be mounted on existing concrete floors.

Available with air or water cooled intercoolers and aftercooler.

A number of innovative features designed to improve efficiency and productivity of any compression operation.

Designed to deliver high volumetric compression efficiency under continuous or intermittent duty.

Dynamically balanced to minimize vibration.

Built for rugged performance.

Unique pressurized crankcase recovers all piston ring blowby, further increasing compression efficiency.

Total oil carryover in most applications is just 10 to 15 ppm, with an optional oil removal system available to reduce oil carryover to .001 ppm.

GreenField compressors do not require external force-fed lubrication to cylinders.

Internal components feature built-in guides and alignment for easy maintenance.

In the case of 2.0 MPa system of entrance pressure, exhaust flow is 450Nm /H fand MPa adjustable exhaust pressure, 35Mpa

Equipment installation form, convenient transportation.

The compressor is driven by motor, belt driven and the compressor is cooled by air cooling.

The use of environmental conditions is as follows:

Temperature 0 C / + 45 C

Humidity < 90%

Tilt angle: transverse +/-22.5o

Longitudinal +/-15o

The compressor unit is installed in a crowbar, and the whole test is done before the factory is out.

The ISO9001 quality system certification was obtained by Han weir.

The compressor is driven by the motor and the belt drive is designed. The spindle of the motor is driven by a belt to drive the crankshaft of the compressor host. The connecting rod mechanism of the compressor converts the rotational motion of the crankshaft into a reciprocating linear motion of the piston, thereby compressing the nitrogen. The motor engine and compressor is mainly installed in a base, the compact structure and convenient transportation.

Gas system

The function of the gas system is mainly to lead the gas to the compressor. After compression at all levels of the compressor, it is introduced to the use place. Start from the first stage filter of the compressor to the end of the stop valve of the last stage exhaust pipe of the compressor. The air system of the compressor is composed of the pipe intake filter, the steam water separator, the cooler, the discharge pipe, the safety valve and so on. The main characteristics of the air road system of the Han weir compressor:

The automatic drainage system, can provide better working efficiency.

Each level of pressure gauge and safety valve to improve the safety operation further

The exhaust port is provided with a check valve, improve the unit better use of the environment.

At the exhaust port, the exhaust temperature of the compressor is too high and the shutdown is protected.

At the exhaust port, the exhaust pressure of the compressor is too high and the shutdown is protected.

HGB7.5-20/350

compressor parameters

|

Model |

HGB7.5-20/350 |

|

Driving mode |

motor drive |

|

Compressor weight |

5000kg |

|

Compressor size |

3200X2200X1900mm |

|

Compressing medium |

NITROGNE |

|

Intake pressure |

2.0MPa |

|

Intake temperature |

35℃ |

|

Working pressure |

35MPa G |

|

flow |

7.5 m³/min ,450NM3/HR |

|

Cooling mode |

Air cooling |

|

Gas temperature after cooler last stage |

3000 m3/h

|

|

Final exhaust temperature (after the rear cooler) |

20 degrees C higher than the ambient temperature |

|

Compression series |

4 |

|

Cylinder number |

6 |

|

Compressor speed |

860 rpm |

|

Axial power |

88KW |

|

Motor power |

110 kW |

|

Type of motor |

|

|

Coefficient of Motor Service |

1.2 |

|

motor speed |

1480 rpm |

|

Motor protection grade |

IP54/ B3/ Isol F |

|

Voltage / frequency |

380V、50Hz |

|

Startup mode |

Soft start |

|

机械噪音Mechanical noise |

85dB |

** Capacity illustrated is based on measurement at 1.013 bar Abs and 20°C. Performance tolerances will be in accordance with tables illustrated in ISO1217: 1996