As the core equipment in the hydrogenation station, the compressor plays an important role in hydrogen pressurization

1.1 Compressor

As the core equipment in the hydrogenation station, the compressor plays an important role in hydrogen pressurization.At present, the hydrogen compressor commonly used in domestic hydrogenation stations mainly include diaphragm compressor, liquid drive compressor and ionic liquid compressor.The diaphragm compressor and liquid drive compressor are mainly used in hydrogenation stations with hydrogen storage pressure not greater than 45MPa, the related technologies of many domestic manufacturers have become increasingly mature; Ionic liquid compressor is mainly used in hydrogen storage pressure of 90MPa hydrogenation station, the domestic pressure grade compressor is still under development, is mainly dependent on imports.

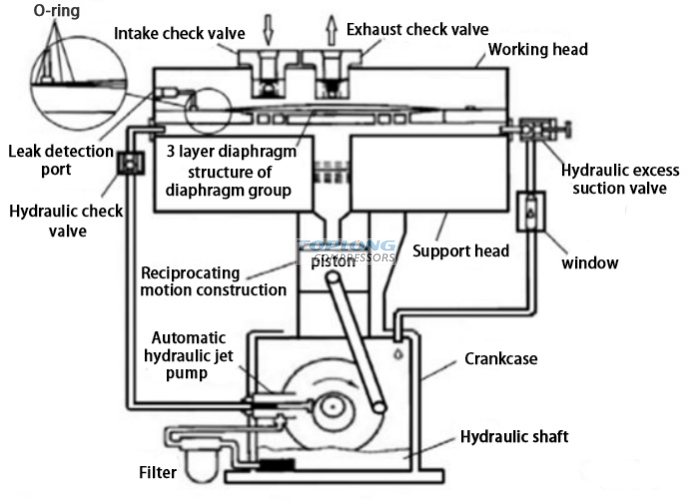

1.1.1 Diaphragm compressor

The diaphragm compressor has a special diaphragm to separate the compressed gas from the outside world.In the diaphragm compressor, the function of the cylinder is completed by a membrane cavity, which is a cavity composed of a cover plate with a dome surface and an elastic diaphragm. The surrounding of the diaphragm is fastened between the cover plate and the body. When the diaphragm flexes and deform, the volume in the membrane cavity changes accordingly, thus completing the compression and exhaust of gas.The metal diaphragm compressor uses liquid force to drive the diaphragm, The diaphragm can be close to the surface of the cover dome, so the relative gap is very small, and the diaphragm between the gas and the liquid is very thin, and the heat dissipation in the compression process is good.At present, the maximum exhaust pressure of the metal diaphragm compressor can reach 70MPa, but because the deformation amount of the diaphragm is limited, the amount of gas treated is generally small.

graph 2:Working principle of diaphragm compressor

1.1.2 Liquid-drive compressor

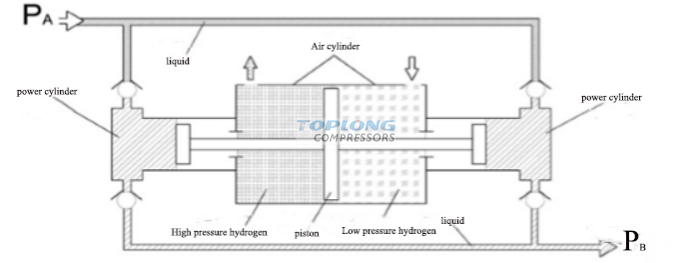

The power cylinder of the liquid drive compressor is directly connected with the working chamber of the reciprocating pump. The piston of the reciprocating pump drives the compressor piston through the liquid (mostly oil) to compress the gas.The middle part of the liquid drive compressor is two opposite cylinders, the plunger is a piston to compress the hydrogen, and the upper part is a control slide valve to release the oil in the power cylinder.This structure can be made into multiple columns and therefore more power.

Fig. 3 schematic of working principle of liquid drive compressor

1.1.3 Ionic liquid compressor

Ionic liquids are commonly used in automation, aerospace, electronics or energy, as engineering fluids or new materials.Ionic liquid itself is almost incompressible, with almost no vapor pressure, and can replace the metal to produce high pressure under isothermal conditions, and can run for a long time without maintenance, saving energy consumption.The structure of ionic liquid compressor is simple, compared with the parts of ordinary compressor, so it is convenient to maintain.At present, it has been used in some natural gas filling stations and hydrogen energy supply stations abroad, and the maximum exhaust pressure can reach more than 90MPa.

1.1.4 Comparative analysis of various types of compressors

The performance comparison of diaphragm compressor, liquid drive compressor and ionic liquid compressor is shown in Table 1 below.

Type | Advantage | Disadvantage |

Diaphragm compressor | 1. High gas purity 2. The relative gap is very small 3. Good heat dissipation during the compression process 4. Widely used in hydrogenation station in China | 1. The single-unit exhaust volume is relatively small 2. The cost of imported equipment is relatively high, about twice that of domestic equipment 3. Frequent start and stop is easy to reduce the compressor life |

Liquid-drive compressor | Single-unit exhaust volume is relatively large | Hydrogen gas can be contaminated |

Ionic liquid compressor | 1. Simple in construction and easy to maintain 2. Low energy consumption | 1. Manufacturing standards are different from domestic standards, and the introduction procedures are complicated 2. The price is higher |

Table 1 Comparison of the performance of diaphragm compressor, liquid drive compressor and ionic liquid compressor Many domestic compressor manufacturers have become increasingly mature in the technical research and development of diaphragm compressor and liquid drive compressor, and a considerable number of hydrogenation stations have begun to apply fully domestic hydrogen compressors.But relatively speaking, the stability and reliability of the domestic compressor still need to be improved.At present, there are a considerable number of domestic hydrogenation station equipment suppliers, purchasing imported compressor heads as the core components, supporting auxiliary parts using domestic procurement and assembly.In this way, for the construction unit, not only improve the reliability of the equipment, but also reduce the equipment procurement cost.At present, most of the 35MPa hydrogenation stations that have been built or are under construction in China use diaphragm compressor or liquid drive compressor.Ion compressor is more suitable for 70MPa hydrogenation station with high filling pressure.